Search:

Metal stress management

for steel goods and structures by metal stress indicators IN-01m, IN-02, IN-03

- operational checking for the facility to be inspected

- feedback of electromagnetic treatment stress relaxation result

usually measured by

metal stress indicators IN-01m, IN-02, IN-03

- stressed state of metal usually determined right after direct measurements

Application examples:

Inspecting and recovering the metal of drilling pipes residual service life

Residual stress of steel pipes inspection and relaxation

Determining the causes of disbalanced gas turbines assemblies

Metal structure analysis

allow to ascertain reliably following features:

- grade of steel or alloy, heat treatment mode

- elementary composition of alloy, presence of impurities

- compliance of metal and products made from ones to GOST requirements

- compliance of product features to certificate of ones

- signs of metal overloads which are impacted in construction working mode

- shape of loads to metal which are lead to destruction

- hearth (point of beginning disruption) and direction of crack distribution in the metal

- residual service life of metal;

- etc.

Technical and scientific consulting

on the following topics:

- special program for defenders of candidate of technical sciences degree on NDT in Russia

05.11.13 «Technique of natural environment, materials and artificial products inspection

- program of training for government experts on speciality

10.4 «Investigation of products made from metals and alloys»

- training coarse for experts, engineers and NDT inspectors «Nondestructive

evaluation of metal stressed state using IN-01m, IN-02, IN-03 instruments»

- etc.

Scientific researches and engineering developments

provided in following industrial branches:

- magnetic and electromagnetic nondestructive testing;

- structure health and environment features measurements and monitoring;

- automation of measures and production processes;

- remote control and management system;

- databases, machine learning, neural networks;

- etc.

Email for research & development requests: support@ntc-spector.ru

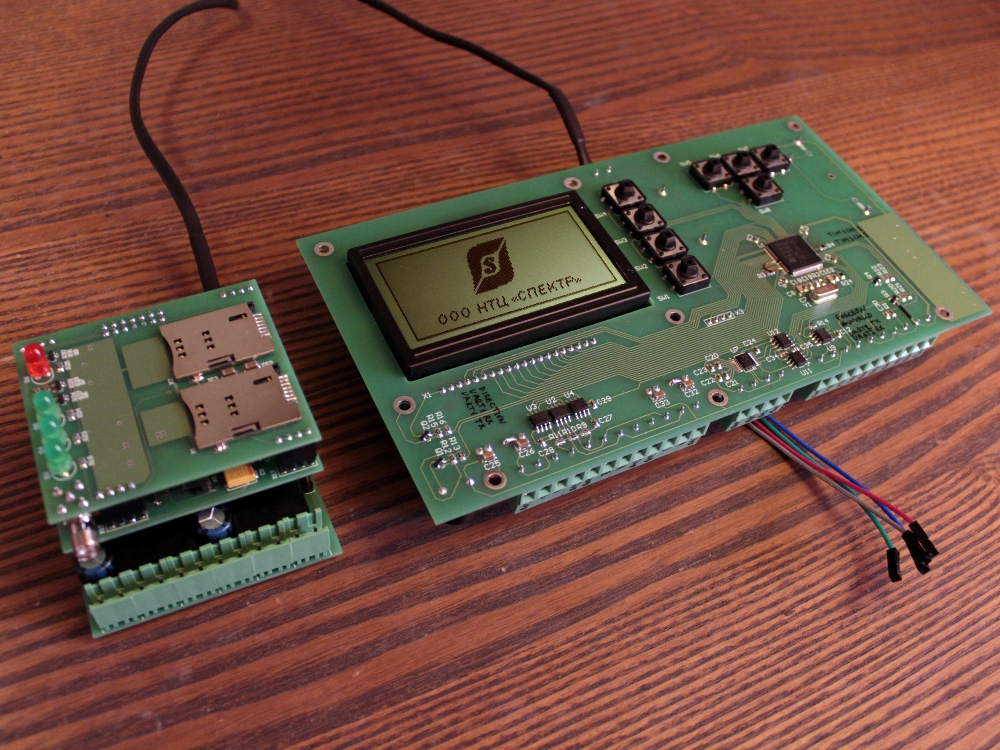

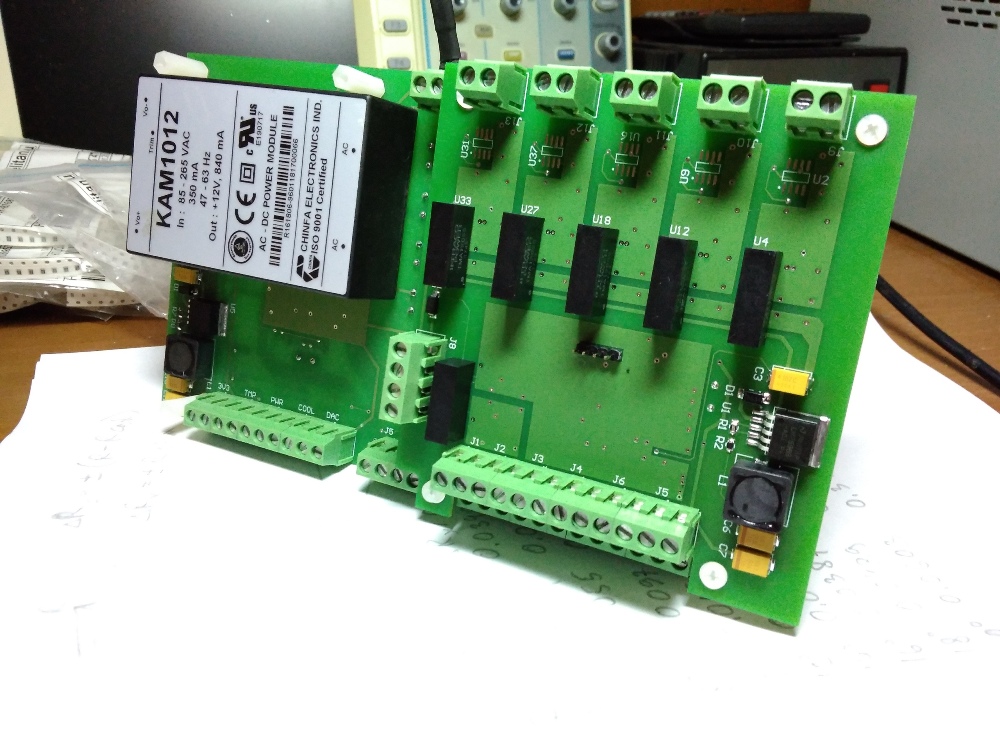

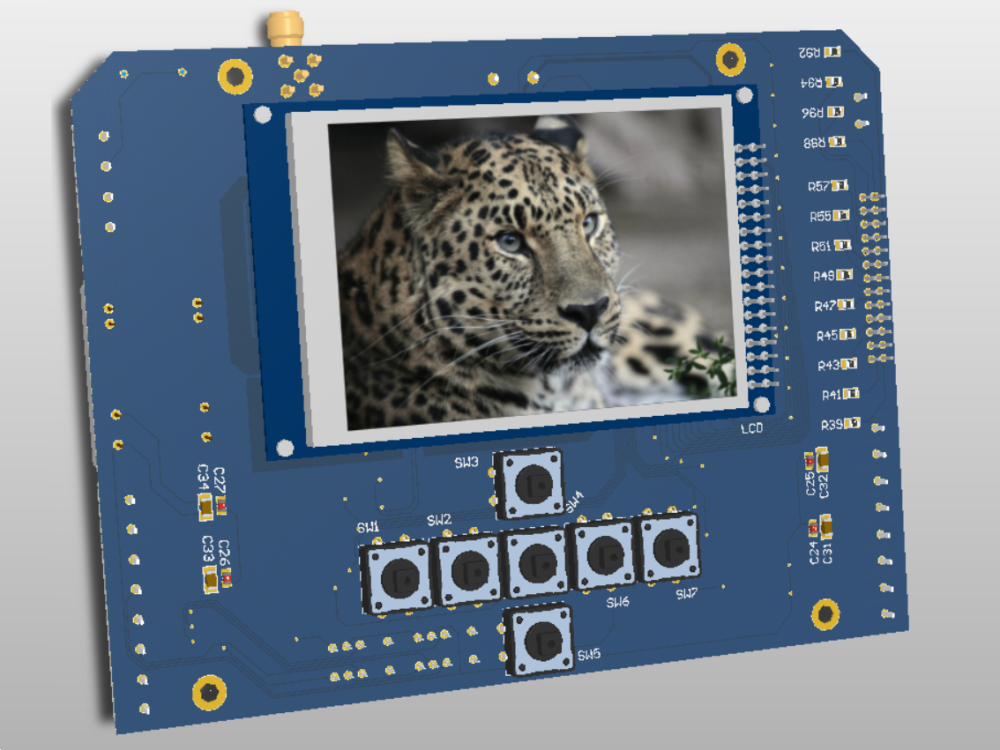

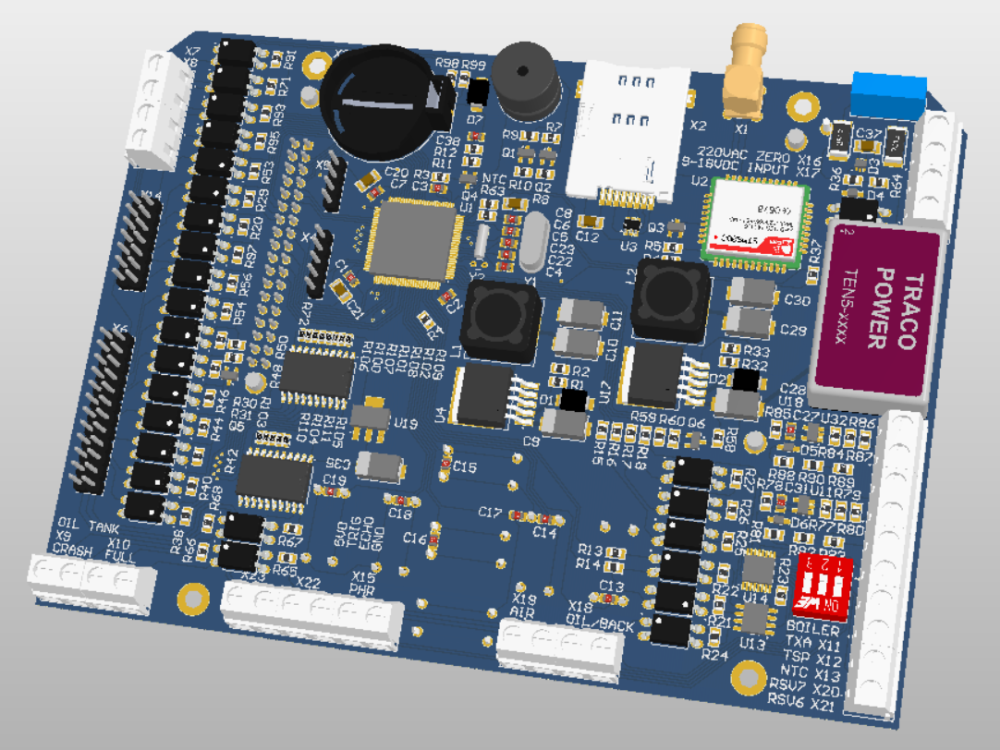

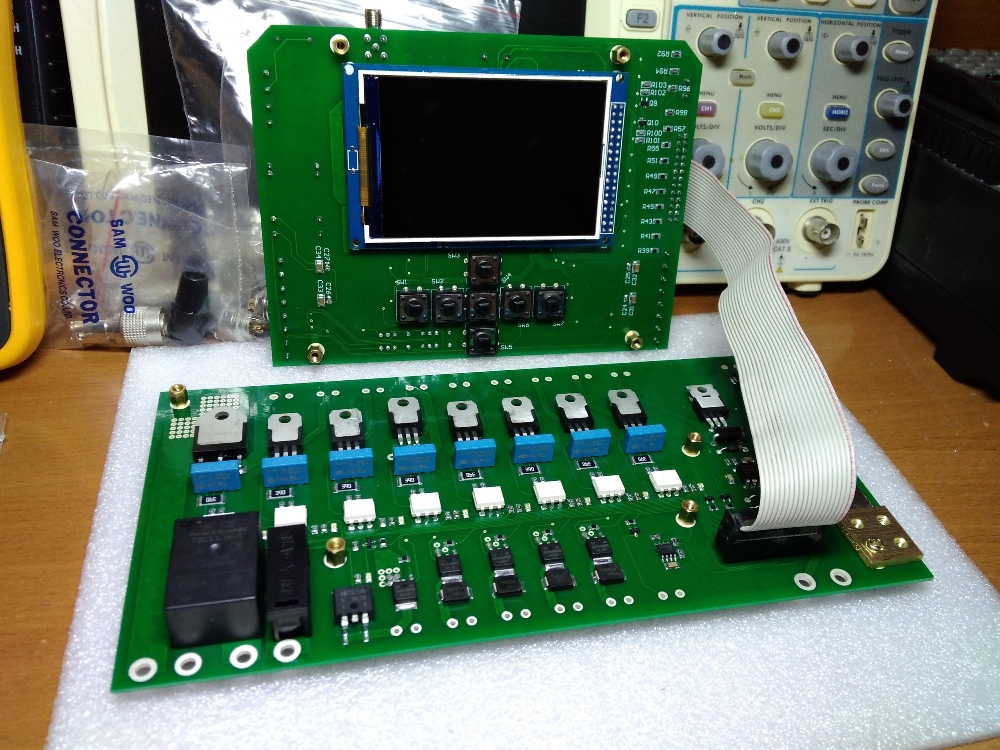

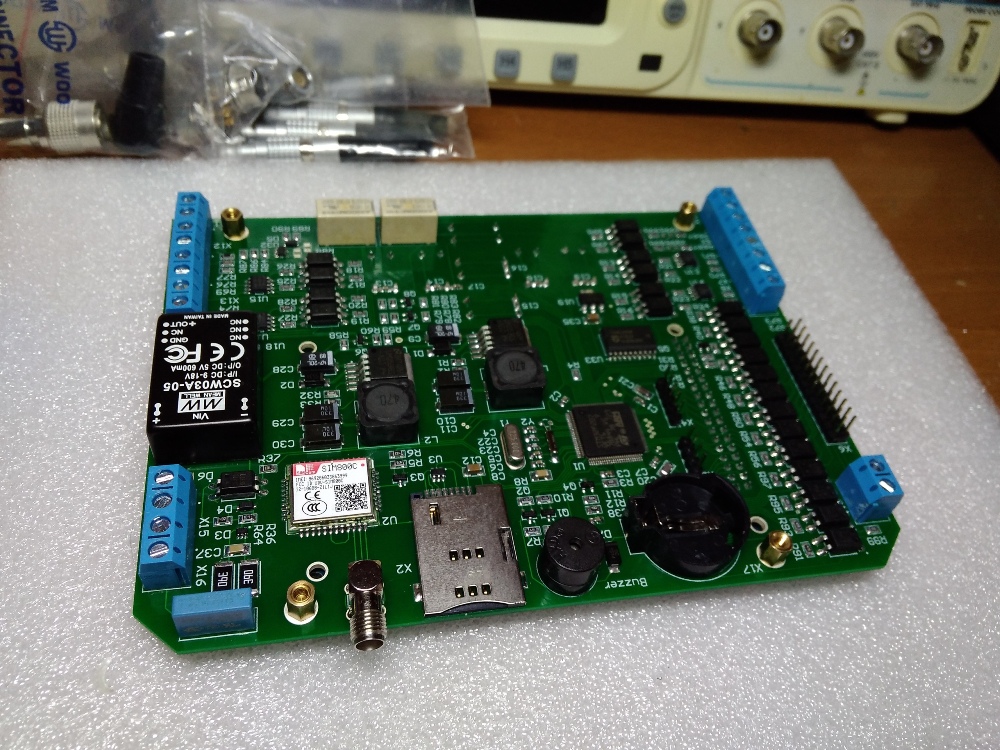

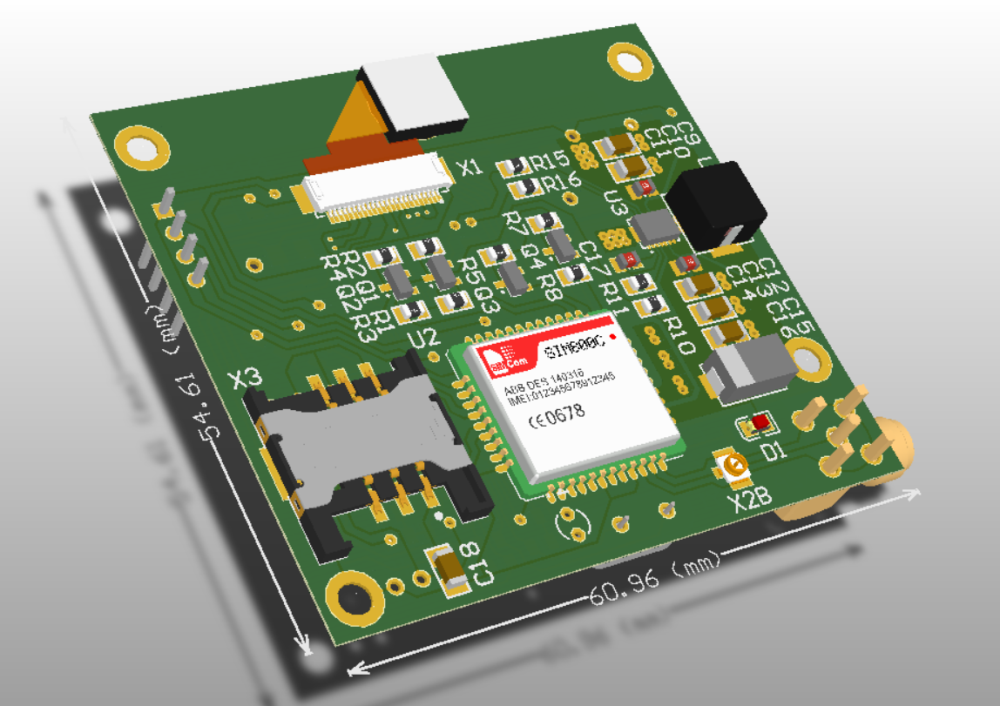

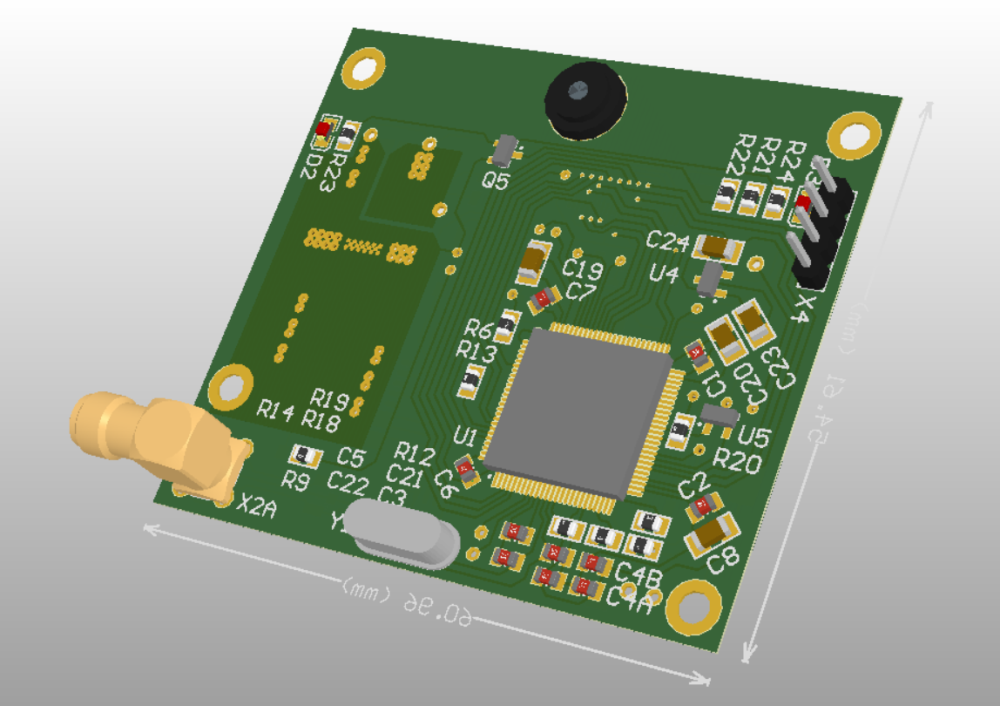

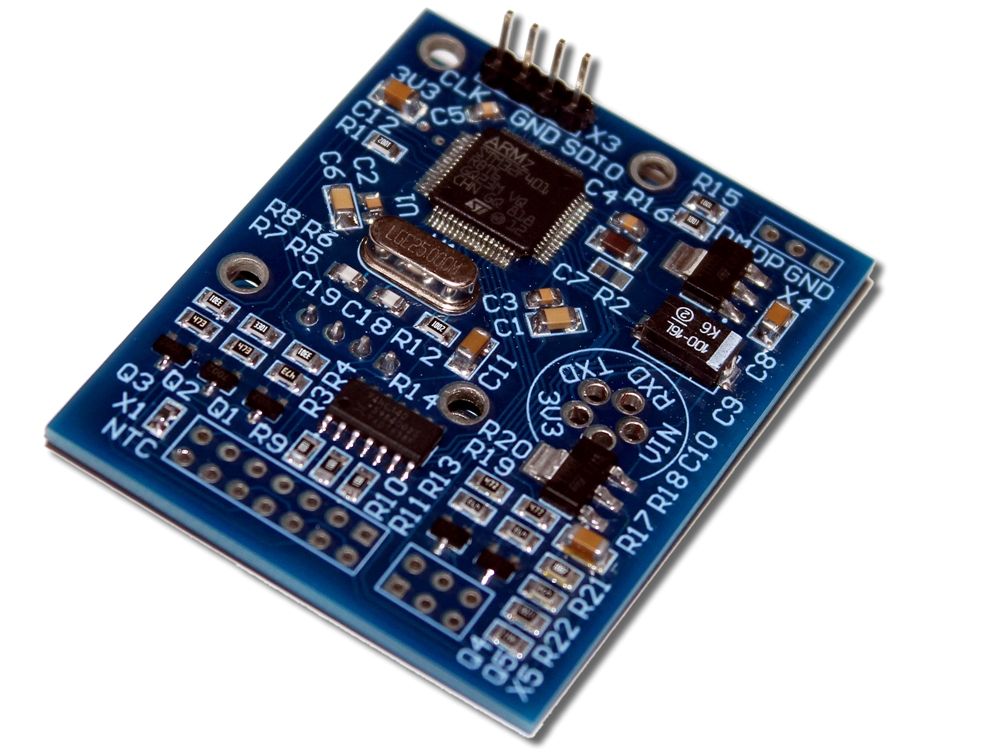

Examples of scientific-engineering developments (under permission of customers):