Search:

STRESSED STATE OF RAILWAYS METAL INSPECTION

BY IN-02 THE SCANNING METAL STRESS INDICATOR

BY IN-02 THE SCANNING METAL STRESS INDICATOR

The mechanical stress accumulated by the metal in local areas of steel rails during long period of time are gradually results to cracks appearance, so they cause the main reason of major accidents on the railways.

In order to prevent the crack appearance in the metal it is necessary that the stress level of steel rail would not exceed the yield limit of metal. The technique of relative measurements implemented into the metal stress indicators allow to specify the severity level of stress state of metal directly on their readouts, therefore IN-02 the scanning indicators are successfully used in steel rails and similar extended steel objects inspection.

Beginning the inspection of steel railway the magnetic measurement unit of IN-02 the indicator should to be installed to the metal through guiding aluminum sledge, width of one could be adjusted for size of rail (figure 1).

Fig.1. IN-02 the scanning metal stress indicator with guiding sledge to scan the stressed state of steel railways metal

A distribution of steel rail metal stress inspected is outputs at once to the display of IN-02 the mechanical stress indicator in real time graphic scan (see an example on the figure 2). During this the inspector can to record the signals measured if need to the plugged-in memory card, to force hold readouts in the display of indicator, etc.

Once the inspection completed the readouts of indicator recorded to the memory card might be transmitted to personal computer or notebook to draw up the results of inspection directly in-the-field (figure 3).

Fig.2. Information on the display of IN-02 the mechanical stress indicator when inspecting the steel railways stressed state of metal

Fig.3. Transmitting the indicator readouts to the notebook and drawing up the results of steel railway inspection stressed state directly in-the-field

Lets consider a several significant features of metal stress distribution observed usually in steel railways inspection by IN-02 the metal stress indicator.

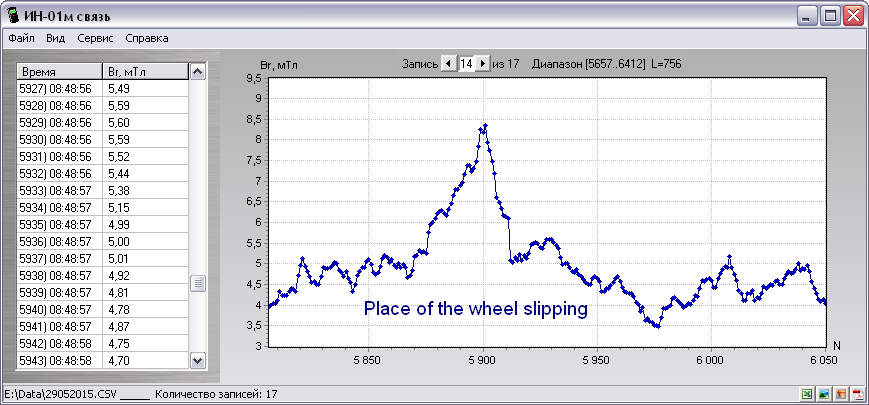

Fig.4. Readouts of IN-02 the metal stress indicator above place of driving wheels slipping occurred at the moment when the locomotive pulled.

(a)

(b)

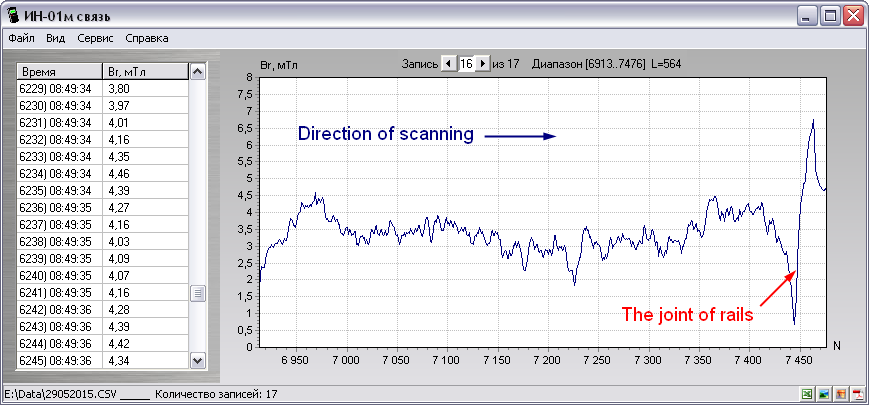

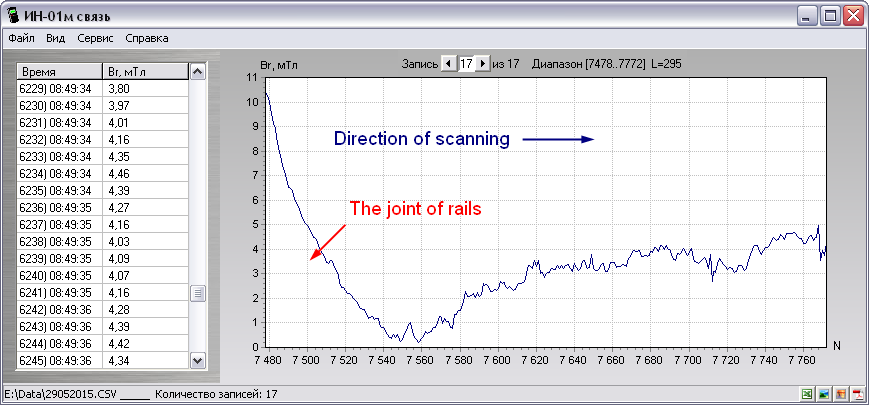

Fig.5. Changing of IN-02 the metal stress indicator readouts as the approaching to the steel rails joint (a) and moving away from one (b)

In the areas of so called «metal cauterizations», appearing on the surface of steel rail due to slipping of the driving wheels occurring at the moment when the locomotive pulled, the slight but rapid increase of mechanical stress of the metal is usually observed (figure 4).

Eventually the stress concentration in «metal cauterized» areas of steel rails would decrease gradually and could return to almost initial state, which is generally caused by the action of two main factors:

- a significant redistribution of the metal stress of steel rail occurs when the train is beginning to go on;

- a relaxation of mechanical stress of metal concentrators when heating and cooling the steel rails due to constant every day oscillations of environment temperature.

The highest mechanical stresses of metal are usually caused by and so located in the welded and threaded joints of the steel rails, exceeding the average level of metal stress for 2-3 times (figure 5). When, the metal stressed state close to the joint is turned out have vast non-uniform distribution which is almost could not be changed by action of environmental factors to the metal.