Search:

A TECHNIQUE TO DETERMINE A REASON

OF HIGH-STRESSED AREAS OF METAL APPEARANCE

OF HIGH-STRESSED AREAS OF METAL APPEARANCE

Providing the metal structure analysis for steel parts is often require to determine a reason of high-stressed condition of the metal observed. Preparing to the metal stress relaxation is also requires to determine its reason.

The high-stressed areas of metal are detected by the metal stress indicators during steel parts and constructions inspecting are usually caused by two general reasons:

1. A concentration of applied stress or residual stress in certain local area of the metal when an external power factor applied to one;

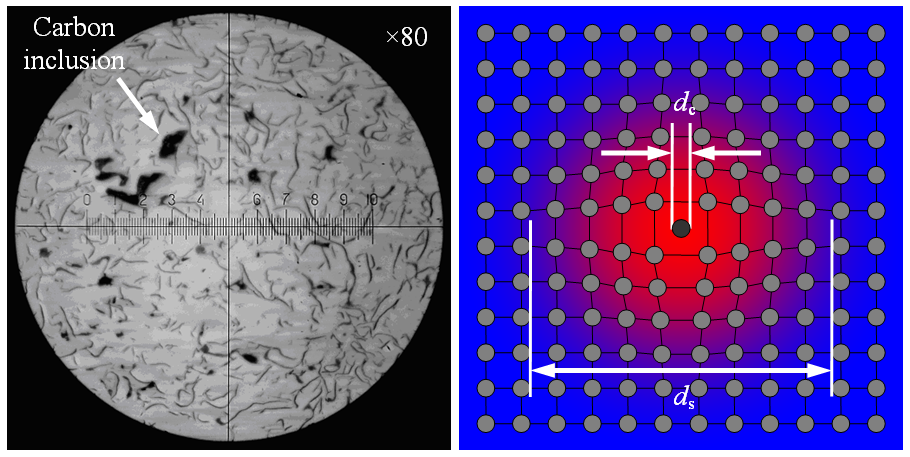

2. Local changes of metal structure (e.g. carbon inclusions presented on the figure 1 are usually appears in the metal then long-time overheating occurred), phase transformations, unallowable variations in elementary chemical composition of metal, etc.

Fig.1. Carbon inclusions as the reason of high-stressed state of metal detected by IN-02 indicator after long-time overheating occurred at 200ºC

In terms of solid state physics these factors would result to microscopic deformations of crystal lattice, around ones the relatively wide and non-homogeneous area with high-stressed state of metal.

A simplified schematic diagram

on the figure 1 shows that width ds of high-stressed area of metal is for much times greater than specific width dc of structure non-homogeneity related to one (actually the ds > dс for hundreds times). For example, experimentally found that there is specific radius of stress concentration area around the edges of crack equal to 30 mm. So in the practice these areas are usually detected easy by the metal stress indicators, however it is impossible to distinguish ones only on the readouts of indicators from areas caused by external power factor was applied (figure 2).

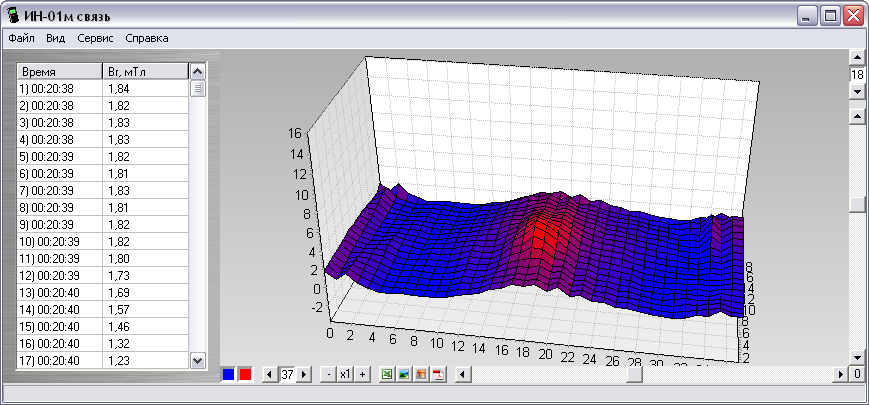

Fig.2. Image of steel part surface having certain area with stressed

state of metal detected by IN-02 the metal stress indicator

In order to determine a reason

of high-stressed areas of metal appearance the additional inspection of object is needed

to carrying by techniques of nondestructive

structure analysis, based on the diagnostic

parameters depending uniquely on structure and elementary chemical composition of metal,

but at the same time negligibly sensitive to mechanical stress.

It is known that the structure of metal determines

significantly the electromagnetic properties of one. For example the changes in elementary

chemical composition or in the structure of metal results to significant change of electric

conductance of one: increasing the grain (crystallite) density in the metal from 10 to 690

grains per 1 cm3 result to increasing the specific electric resistance for 10-20%,

which can be detected by convenient portable eddy current conductance meter.

Therefore the reasons of high-stressed

areas of metal appearance detected by IN-01m and

IN-02 scanning gages would be determined immediately

if the eddy current conductance meter is used together with one:

1. If readouts of the eddy current

conductance meter into and beyond of local area with high-stressed state of metal detected

are the same, when the reason of its appearance is applied stress or residual stress

concentration.

2. If readouts of the eddy current

conductance meter into and beyond of local area detected are the different even if slightly,

then most probable reason of its appearance is local structure changes of metal.

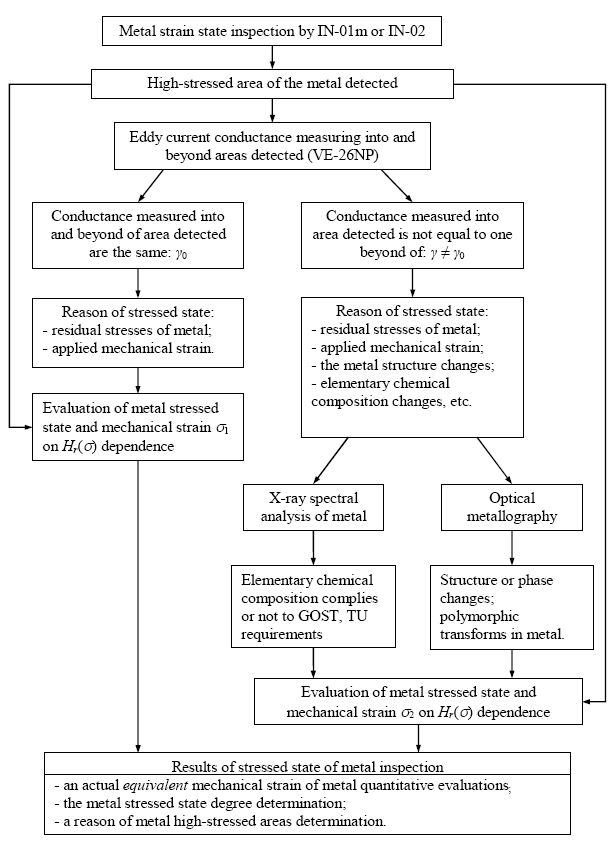

Fig.3. Flowchart of

analytic technique to determine a reason

of high-stressed areas of

metal appearance

On the figure 3 the flowchart of analytic technique to determine

a reason of high-stressed areas of metal appearance based on combined application of IN-01m

or IN-02 the metal stress indicator and eddy current conductance meter VE-26NP (figure 4),

also as the analytic equipment used in the practice of metal structure analysis.

IN-01m

IN-01m VE-26NP

VE-26NP

Fig.4. Instrumental kit for high-stressed

areas of metal detection

and reasons of their appearance determination

As result of experimental investigations carried out in

cooperation of the Central Laboratory of Expertise of Russian Federation the technique to inspect stressed state of steel parts and to determine a reason of high-stressed areas of metal detected is created and approved.

Examples of technique described application on the real

industrial facilities are given in section Useful information | Application examples.